Pennine Healthcare is proud to be one of the UK’s leading, employee owned, manufacturer and distributor, of single-use sterile and non-sterile Ward & Theatre Consumables and Custom Procedure Packs, as well as one of the leading suppliers of PPE to healthcare settings.

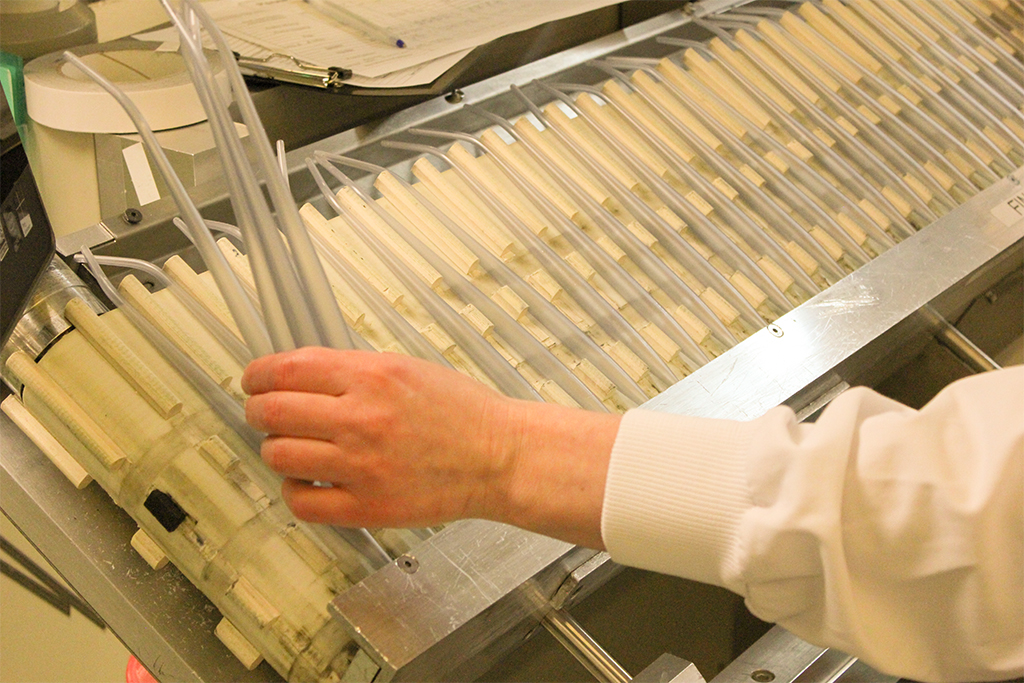

Since our incorporation in 1963, the business has grown year on year, and we market and distribute products in over 50 countries worldwide, employing around 180 people at our purpose-built premises in Derby. The site covers almost 100,000 sq ft, incorporating an area for storage and loading, capable of handling over 4,500 pallets. We are also home to some of the most sophisticated technology in the industry, including three state-of-the-art clean rooms, operating to BS EN ISO 14644-1 standards.

In line with our ISO 13485 accreditation, Pennine has a policy of continual improvement to meet the needs of all our customers, while continual investment in people, training, and technology has enabled us to provide an increasingly wide range of user-friendly, high-specification products. As a healthcare manufacturer, we understand the importance and requirements of the products we produce, combining this with promoted standards of safety, health, and welfare to provide a healthy and safe working environment for all staff members.

We are committed to minimizing our direct impact on the environment and are continually working towards improving our environmental performance, integrating recognised best practices into all our business operations.

We were proud to become an Employee-Owned Trust in 2021, ensuring the business stayed in the city of Derby, while recognising staff for their hard work and commitment throughout the years.

In 2023, we were delighted to win the prestigious MAKE UK Midlands & East of England Manufacturing Matters Award, in line with our commitment to UK Manufacturing, as well as launching our Commercial Partnership Offering – specialising in Medical Device Packaging, Kit Assembly, and Contract Manufacturing.

We have a UK, International and Veterinary division here at Pennine Healthcare…

Within the UK, Pennine’s focus is on serving the needs of our much-valued NHS. Our products can be found across the UK in hospitals, ensuring that we meet both the clinician and patients’ needs. Many of our products are available on Frameworks across the UK also.

We partner with distributors to provide the most environmentally friendly route to hospitals to consolidate supply, whilst also retaining the flexibility of working direct where our customers feel that services adds more value.

We also supply a wide range of Private Hospitals and B2B customers and pack manufacturers allowing us to bring our UK Manufactured range to the market across the segments

As a business, we also enjoy working on product development and innovative product projects, whilst offering customers full flexibility with our OEM Manufacturing and Custom Procedure Packs.

With over 30 years of experience in UK sales, we can provide a wealth of knowledge in terms of product training, shipping, product implementation and ultimately offer our knowledge and excellence in customer service.

One of Pennine’s major success stories has been our expansion into export markets. We have established a core network of overseas distribution outlets in all major European countries and many other locations across the world. Our distributors are all carefully selected so customers and end-users receive first class local support and have easy access to our ever-increasing range of products.

With over 30 years of experience in international sales, our Export Team can provide a wealth of knowledge in terms of export shipping, shipping documentation, product training, languages and ultimately offer our export distributors excellence in customer service and the full support required to market our products in their dedicated territory.

Building on the expertise of Pennine Healthcare, Pennine Veterinary offers a wide range of high quality, value for money, UK manufactured surgical products. We aim to be responsive and adaptable to the market and therefore work closely with veterinary surgeons and staff to find the best value for money products which match their clinical needs.

Whilst we are primarily focused on supplying customised and generic procedure packs and disposable drapes and gowns, we are also very keen on new product development and encourage our customers to approach us with any ideas they may have.